William LeMessurier - The Fifty-Nine-Story Crisis: A Lesson in Professional Behavior

William LeMessurier served as design and construction consultant on the innovative Citicorp headquarters tower, which was completed in 1977 in New York. The next year, after a college student studying the tower design had called him to point out a possible deficiency, LeMessurier discovered that the building was indeed structurally deficient.

Part 1: History of Skyscrapers

Part 2: LeMessurier's Innovative Citicorp Design

Part 3: The Discovery of the Change from Welds to Bolts

Part 4: Exploring the Effects of Quartering Winds

Part 5: Further Evidence of the Danger

Part 7: Accomplishing the Repair Without Causing Panic

Part 8: The Final Touch: LeMessurier's Good Name

Addendum: The Diane Hartley Case

William LeMessurier, one of the nation's most distinguished structural engineers, served as design and construction consultant on the innovative Citicorp headquarters tower, which was completed in 1977 in New York. The next year, after a college student studying the tower design had called him to point out a possible deficiency, LeMessurier discovered that the building was indeed structurally deficient. LeMessurier faced a complex and difficult problem of professional responsibility in which he had to alert a broad group of people to the structural deficiency and enlist their cooperation in repairing the deficiency before a hurricane brought the building down.

His story was recounted in detail in "The Fifty-Nine-Story Crisis," which appeared in the May 29, 1995 issue of The New Yorker, and on November 17, 1995, LeMessurier himself went to MIT, from which he received his doctorate, to speak to prospective engineers about the decisions he had to make and the actions he took. In the video from that event seen below, LeMessurier discusses ethical dilemmas he faced with structural deficiencies in the design of the Citicorp headquarters.

The Story of the Citicorp Tower

Part 1: Background and the History of Skyscrapers

The skyscraper, like any other architectural form, had gone through a long period of evolution. After Elisha Otis's successful introduction of the first safety-brake-equipped elevator in the 1850s and the introduction of steel-frame construction, buildings began to grow upward. In 1910, the Metropolitan Life Building broke all records for height until that time: it was 50 stories high.

By the 1930s, with the construction of the 102-story Empire State Building skyscrapers, thanks to their widespread success, had begun to sprout in many cities worldwide. Areas populated with these tall buildings found themselves growing, literally, ever upward. The skyscraper, coupled with the introduction of modern, efficient subway systems in cities like New York, made it possible for companies to employ workforces unprecedented in size. Consequently, city populations increased immensely.

By 1930, daring, creative architects and engineers had even begun to depart from what had been accepted as the "traditional" method of designing and constructing skyscrapers. Innovations in skyscraper design such as lighter materials, increased window area, and cantilevered supports, resulted in taller, lighter, and slimmer buildings. For instance, Chicago's record-breaking Hancock Building, incorporating an innovative system of diagonal bracing that allowed the building to be much leaner and lighter than it could be if it had been constructed in a traditional manner.

By the early 1970s, when Citibank began plans for a huge new headquarters tower in midtown New York, the art of designing and building a strong, safe skyscraper seemed nearly perfected.

Part 2: Citicorp Design

William LeMessurier was one of the country's most distinguished structural engineers when his Cambridge firm was called upon to act as a consultant to the planned Citibank corporate headquarters. LeMessurier had a vast array of experience with skyscrapers; the first building he designed, Boston's State Street Bank, incorporated an inventive cantilever girder system, and his famous Boston Federal Reserve Bank was designed so that an airplane could, quite literally, fly directly through what appeared to be a large hole in the building.

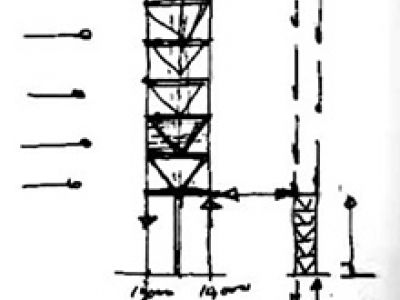

LeMessurier's experience with innovative designs was fortunate, since there was a criterion peculiar to the planned Citibank building. A church had partial ownership of the block where Citicorp planned to build. As a resolution, Citicorp agreed to build a new free-standing structure, located at one corner of the lot, to replace the current antiquated, dilapidated church. In return, the church granted "air rights" above its part of the block to Citicorp. (Pictured: The bottom part of the first rendering of the Citicorp tower design, clearly showing the nine-story high, mid-wall-mounted stilts that would need to support the building.)

In order to provide space for the new church, the Citicorp tower would therefore have to be situated on nine-story-high stilts, so the church could be constructed underneath. However, the church was to be located at a corner of the block, not in the middle of a block. This meant that the Citicorp tower's stilts would have to be in the middle of each of its walls, and not at the building's corners -- an unprecedented feat of engineering if it could be accomplished.

The innovative LeMessurier sketched an idea for the Citicorp tower's framework and column support system. It called for large diagonal girders throughout the building. The girders would transfer the tower's great weight to the four huge columns that would anchor the structure to the ground. The new church could then be constructed as planned, underneath one of the tower's corners.

Part 3: The Discovery of the Change from Welds to Bolts

The Citicorp tower was constructed using LeMessurier's diagonal-bracing design, and work was finished in 1977. LeMessurier's innovation translated into a great weight savings; the tower was unusually light for its size. However, this meant that it would have a fair tendency to sway in the wind, so a tuned-mass damper was installed at the top of the building. The inertia of this 400-ton concrete block, which floated on pressurized oil bearings, worked to combat the tower's expected slight swaying. The Citicorp tower was the first structure ever to incorporate mechanical assistance to combat wind sway.

In May 1978, LeMessurier, acting as structural consultant to a new building being planned in Pittsburgh, again thought of using a sort of diagonal brace as part of his design. As in the Citicorp tower, the braces were intended to be joined with full-penetration welds, but the process of welding, though it resulted in extremely strong joints, was expensive and time-consuming. A potential contractor for the Pittsburgh construction job pointed this out to LeMessurier, who immediately thought to counteract the contractor's fears with the success story of his Citicorp tower and its welded joints.

Unknown to LeMessurier, however, was that during the Citicorp tower's construction (the tower under construction is pictured on this page), the Citicorp contractors had decided, based on the cost of welding, to put the braces together using less expensive bolted joints. Though bolted joints were weaker than welded joints, the New York contractors had agreed that welds would be unnecessarily strong and that bolts would be sufficient for the job.

When LeMessurier referred the Pittsburgh contractor, concerned over the cost of welding, to the successful Citicorp job, he was told of the substitution of bolts for welds in the Citicorp project. LeMessurier did not consider the change to pose a safety hazard, however, since the substitution was rather reasonable from an engineering standpoint, and there wasn't any reason for LeMessurier, a distant consultant, to have been previously informed. This assessment would change over the next month, however, as LeMessurier would soon encounter new data indicating that the switch from welds to bolts compounded another danger with potentially catastrophic consequences.

Part 4: Exploring the Effects of Quartering Winds

In June 1978, a month after LeMessurier was told of the switch from welds to bolts in the Citicorp building, he received a telephone call from a student. This student's professor had been studying LeMessurier's Citicorp design and had concluded that LeMessurier had put the building's nine-story supports in the wrong place. The supports belonged on the tower's corners, according to this professor, not at the tower's midpoints.

The professor had not understood the design problem that had been faced, so LeMessurier explained his entire line of reasoning for putting the tower's supports at the building's midpoints. He added that his unique design, including the supports and the diagonal-brace system, made the building particularly resistant to quartering, or diagonal, winds -- that is, winds coming on the diagonal and so hitting two sides of the building simultaneously. Pictured is a diagram of why perpendicular winds cause sway in a building.

Shortly thereafter, LeMessurier decided that the subject of the Citicorp tower and quartering winds would make an interesting topic for the structural engineering class he taught at Harvard. Since at the time the requirements of the New York building code, like all other building codes, had covered only perpendicular winds, LeMessurier did not know how his design would fare in quartering winds.

Interested to see if the building's diagonal braces would be as strong in quartering winds as they had been calculated to be in perpendicular winds, LeMessurier did some computations. He found that for a given quartering wind, stresses in half of a certain number of structural members increased by 40 percent.

Then he became concerned about the substitution of bolts for welds. Had the New York contractors taken quartering winds into account when they replaced the welds with bolts? Had they used the right number of bolts? The second question was particularly important -- a 40 percent increase in stress on certain structural members resulted in a 160 percent increase of stress on the building's joints, so it was vital that the correct number of bolts be used to ensure that each joint was the proper strength.

What he found out was disturbing. The New York firm had disregarded quartering winds when they substituted bolted joints for welded ones. Furthermore, the contractors had interpreted the New York building code in such a way as to exempt many of the tower's diagonal braces from loadbearing calculations, so they had used far too few bolts.

Shaken, LeMessurier reviewed old wind-tunnel tests of the building's design against his new quartering-wind calculations (these tests had modeled a large part of midtown Manhattan), and found that under adverse weather conditions, the tower's bracing system would be put under even further stress. The innovative tuned-mass damper, designed to reduce the building's normal slight swaying, was not designed to keep the building from being blown down in a major storm; this further worried LeMessurier.

What he found out was disturbing. The New York firm had disregarded quartering winds when they substituted bolted joints for welded ones. Furthermore, the contractors had interpreted the New York building code in such a way as to exempt many of the tower's diagonal braces from loadbearing calculations, so they had used far too few bolts.

Part 5: Further Evidence of the Danger

LeMessurier now believed there might be serious danger. He turned to Alan Davenport, a Canadian consultant during the building's design. Davenport, who had run the original wind tunnel tests, now ran the tests again, using new calculations to reflect quartering winds and the change from welds to bolts.

The results, when compared with the building's original testing, confirmed LeMessurier's suspicions about increased stress in some of the building's structural members. His concern grew, since the results indicated that a 40 percent theoretical increase in a member's structural stress would be much greater under real-world conditions. During a storm, the whole building could shake, causing the structural members to all vibrate synchronously.

LeMessurier worked through the revised wind tunnel data, and quickly discovered that the entire building was vulnerable to a total structural failure -- if a storm pulled a joint apart on the 30th floor, the whole building would collapse. A "sixteen-year storm," that is, a storm occurring once every sixteen years, would have the strength to cause total structural failure. Though the electric tuned-mass damper had an enormous steadying effect on the building, and might help to reduce the stress on that joint, a strong storm would knock out the electricity necessary for running the damper.

Solving the problem was not difficult from an engineering perspective; heavy steel welded "Band-Aids" over the joints would give the building more strength than it was even originally designed to have. But it was the last day of July, and in order to complete repairs before the start of hurricane season, LeMessurier would have to announce the building's vulnerability and take responsibility upon himself. Doing so could cost LeMessurier his career and reputation as a structural engineer. He did not know how his news would be received by Citibank leadership, city officials, or the general public.

Part 6: Mobilizing Support

On July 31, 1978, LeMessurier contacted the lawyer of the architectural firm that had retained him as its structural consultant for the Citicorp tower and then the firm's insurance company. As a result, a meeting was arranged the following day with several lawyers for the insurers, to whom LeMessurier related the entire story. The lawyers soon decided to bring in a special consultant -- Les Robertson, a respected structural engineer. Robertson listened to LeMessurier's description of the situation and soon took a more critical view than even LeMessurier himself. Robertson did not believe, for instance, that the tuned mass damper would serve as a safety device despite LeMessurier's assurances that generators could keep the dampers running during an electrical power loss.

Citicorp had to be informed of the danger, so LeMessurier and his partner went about contacting Citicorp's chairman, Walter Wriston. Initially, Wriston was unavailable to them, but LeMessurier's partner was able to arranging a meeting with Citicorp's executive vice president, John Reed, who had engineering experience and played a part in the construction of the tower. LeMessurier detailed the situation once more. When prompted for a cost estimate, LeMessurier guessed that one million dollars would be sufficient. He also explained that the repairs could be done without inconvenience to the tenants by isolating the bolted joints within plywood 'houses' and doing the necessary work at night within those 'houses.'

Reed appreciated the gravity of the situation, and arranged for a meeting with Wriston on August 2, at which point LeMessurier once again told his story. Much to his relief, Wriston recognized the importance of the tower as Citicorp's new corporate emblem, and so readily agreed to the repair proposal. He approved a plan to install emergency generators as a backup power supply for the tuned mass damper, and oversaw much of the relations with the public as well as with the building tenants.

The next day, LeMessurier met with two engineers from the construction company that was to perform the repairs. After examining the joints, these engineers approved LeMessurier's plan to reinforce the bolted joints with welded "Band-Aids."

Before undertaking the repairs, several steps were necessary. LeMessurier contacted the company that had constructed the tuned mass damper to help assure the device's continuous operation. Meteorological experts were retained in order to give advance warning of any storm that could cause the building's destruction. LeMessurier reluctantly agreed with Robertson that, as a further precaution, an emergency evacuation plan for the building and the ten-block-diameter surrounding neighborhood be drafted. In its final form, the plan was to involve up to 2,000 emergency workers provided by the Red Cross.

LeMessurier had to explain the situation to city officials, both to secure their cooperation with the evacuation plan and to comply with the building code. They responded with approval and encouragement, rather than the cynicism that LeMessurier expected. They too recognized both the seriousness of the problem and the immediate need to solve it. Energy was not wasted on rancor or placing blame.

The final task, the one that LeMessurier most dreaded, was informing the press of what was going to be a major undertaking on the brand-new Citicorp tower. An initial press release was issued. It indicated that the building was being refitted in order to withstand slightly higher winds. This was true to some extent, for the meteorological data suggested that the winds for that year were going to be somewhat higher than normal. But the New York Times, for one, was sure to express further interest in what could be a very juicy story. After an initial phone call from a reporter, though, LeMessurier found an unexpected reprieve in a citywide press strike.

Part 7: Repairing Citicorp Tower

Repairs to the Citicorp building commenced immediately. The plan of action was to expose each bolted joint in the building by ripping away the flooring and walls around it, to cover each joint with a plywood 'house' in order to minimize any visible signs that things were awry with the building's structure, and to complete the repair welding at night when the tenants were not in the building, so as not to inconvenience them.

The pace of work was fast. Parts of the interior around the bolted joints were torn up at night and put back together in the morning. LeMessurier occupied himself with repair process calculations. Les Robertson calculated how to repair the joints, and, suspecting that other components of the building could be vulnerable, went about investigating the floors, columns, and braces for weakness.

The repair work was in full swing on the first of September, when a hurricane moving toward New York was detected. The news was met with alarm. The partial repairs -- along with the tuned mass damper -- greatly improved the building's strength, but no one wanted to see it tested. There was great relief when the hurricane moved out over the ocean.

Two weeks later, repairs had progressed to the point that, with no storms predicted, the elaborate evacuation plans could be scrapped. The next month, repairs were complete. Even if the tuned mass damper were to fail, a 700-year storm would not pose a threat to the Citicorp Center.

The engineering problem had been solved, and today the repaired building now exceeds even its originally intended safety factor.

Part 8: The Final Touch: LeMessurier's Good Name

LeMessurier feared for his career but did not allow any worries or self-protective impulses to sidetrack his attention from carrying out the repairs. In the middle of September, when repairs were almost complete, Citicorp notified LeMessurier and his partner that it expected to be reimbursed for the cost of the repairs.

The estimated total cost for the building's repair ranged between a high of $8 million for the structural work alone, given by one of the construction companies involved, to $4 million, which, according to LeMessurier, was the Citicorp estimate (Citicorp did not make public its estimate).

LeMessurier's liability insurance company had agreed to pay $2 million, and LeMessurier brought that figure to the negotiating table. The Citicorp officials eventually agreed to accept the $2 million, to find no fault with LeMessurier's firm, and to close the entire matter.

A relieved LeMessurier nevertheless expected his insurance company to raise the premiums on his liability insurance. He would, he reasoned, appear as an engineer who had bungled an expensive job and brought about a large cash settlement.

At a meeting with officials from the insurance company, LeMessurier's secretary was able to convince them that LeMessurier had "prevented one of the worst insurance disasters of all time!" Far from behaving in an incompetent or devious manner, LeMessurier had acted in a commendable way: he had discovered an unforeseen problem, acted immediately, appropriately, and efficiently to solve it, and solved it.

LeMessurier's handling of the Citicorp situation increased his reputation as an exceptionally competent, forthright structural engineer. It also prompted his liability insurers to lower his premium.

Addendum: The Diane Hartley Case

Case Author(s): Caroline Whitbeck

In 1978 Diane Hartley was an engineering student at Princeton, studying with David Billington who was offering a course on structures and their scientific, social, and symbolic implications (subsequently titled, “Structure and the Urban Environment”). This course interested Diane Hartley early in her engineering studies and led her to pursue her undergraduate thesis with Billington, a thesis titled “Implications of a Major Office Complex: Scientific, Social and Symbolic Implications.”

In her thesis, Hartley looked into the Citicorp Tower, which had been recently built and was interesting to her for a number of reasons, including its innovative design. That design not only allowed a preexisting church to remain at ground level, but, because it left more open space at ground level, was permitted to be taller than zoning laws would otherwise have allowed.

When she contacted William LeMessurier’s firm (the engineering firm that built the Tower), they put her in touch with Joel S. Weinstein in their New York office, at the time a junior engineer with the firm. Mr. Weinstein sent her the architectural plans for the Citicorp Tower and many of his engineering calculations for the building. She reports that, at the time, she thought it odd that she did not see initials of another person beside those calculations, because the usual practice was for such work to be checked and initialed by a second engineer.

When Diane Hartley calculated the stresses due to quartering winds (winds hitting one of the corners of the building and so hitting two sides of the building at once), she became concerned that quartering winds produced stresses that were significantly greater than those produced by winds hitting a single side. Although calculation of stresses produced by quartering winds was not required by the then current building code, she assumed those calculations would have been done for a building with a design as innovative as the Citicorp Tower, and asked Joel Weinstein for his calculations of the effects of quartering winds.

What I do not know and cannot know is whether the load bearing calculations for the Citicorp Tower were done by Weinstein and went unchecked. whether calculations for the stresses of quartering winds were done but not included in the information provided to Diane Hartley, or whether the calculations were never done. In any case, such calculations, though not required by the building code of the time, would have been expected for such an innovative design. This is what Diane Hartley believes, but LeMessurier says he was prepared to argue (if Citicorp sued him or his firm for negligence for failing to consider quartering winds) that such calculations would have been unusual.

Recently a coworker (who was acquainted with David Billington) asked LeMessurier whether the student might have been a woman. LeMessurier responded that he didn't know because he had not actually spoken with the student.

The story of the Citicorp Tower is at least a story of evaluating previously overlooked hazards to the public safety and marshaling resources to remedying them. It is also a cautionary tale about how new engineers may lack confidence in their own engineering reasoning to press their recognition of safety problems, and how readily (in the United States

Thought/Discussion questions:

- Whose interests are at stake in this case?

- What, if any, were the constraints on the actions of each?

- Was anything wrong/undesirable or especially praiseworthy in the situation or the reasoning of any of the actors? Could each have behaved better?

- What are the obligations and responsibilities of a junior engineer working on an innovative design for a building in a structural engineering firm?

- What are the obligations and responsibilities of a senior engineer working on an innovative design for a building in a structural engineering firm?

All images displayed herein, unless otherwise noted, courtesy William LeMessurier. This page and supporting pages were created by Eric Plosky for Caroline Whitbeck at the Massachusetts Institute of Technology.

After several decades of the Citicorp Building story being taught in engineering ethics courses, new studies have recently challenged the conventional interpretation in a belated response to Kremer’s question (Kremer 2002). Using computer technology unavailable at the time the Citicorp Building was designed, researchers have shown that the governing wind loads on Citicorp are due to head-on (face) winds and not quartering (corner) winds (Park et al. 2019; Duthinh 2018). This finding agrees with the wind tunnel tests (Isyumov 1975) performed in the 1970s to inform the wind design of Citicorp. What then caused LeMessurier to perform the emergency welding of reinforcing straps on the joints of the multi-story chevron braces that channel structural loads to the mid-side base columns? A recent study (Duthinh 2020) points to a possible misconception in dealing with simultaneous loads on two adjacent building faces under the action of quartering winds.

With this hindsight, the importance of the student in attracting LeMessurier’s attention to a possible problem becomes more questionable. That student has long been assumed to be Diane Hartley (Whitbeck), who wrote an architecture bachelor thesis at Princeton University on the Citicorp Building (Hartley 1978). Yet LeMessurier remembered a call from a male engineering student from New Jersey. In fact, I am that student, and here is my story.

In spring 1978, I was a freshman architecture student at the New Jersey Institute of Technology in Newark, New Jersey. In my class in the basics of structural engineering, Professor Zoldos asked students to report on a building of unusual structural design. I had been reading about the CitiCorp Building in various architecture journals at the time, such as Architectural Record and Progressive Architecture. I thought it was a very interesting building and, since it was in nearby New York City, I could go see it.

I began writing my paper using the information available from the magazines and a visit to the CitiCorp tower. The building was scary with its massive columns holding it way up in the air. I’d never seen anything like it. Professor Zoldos also seemed very interested and familiar with this new building and its extremely daring structural design. The details are a little hazy as I try to recall, but Professor Zoldos expressed some reservations about the building. He thought it might have been overly ambitious in its attempt to create a cutting-edge design. In particular, Professor Zoldos mentioned the columns being located not at the corners but in the middle of the sides of the building. I remember him saying that the first job of a structural engineer is to design a safe building. I was surprised by his criticism of this great, new, and much-admired building. I was a very naïve student at the time and thought that any architect that designed such an amazing building was beyond criticism.

I decided to call the architect, Hugh Stubbins. His office suggested that I call the structural engineer instead. So I called William LeMessurier in Cambridge, Massachusetts, and found myself very impressed to be talking with the structural engineer of the CitiCorp Building. We talked about the building and its perilous columns. LeMessurier gave me lots of information, but after a few minutes, said he had to go to a meeting and would call back. I did not think he would, but about a half hour later, he did. I was stunned.

We talked for another 15 minutes or so, discussing the columns and their location. Looking back, I must have seemed hopelessly ignorant to LeMessurier, telling him that my professor thought the building columns were in the wrong places. I also asked about the tuned mass damper I’d read about. It was very hard for a freshman architecture student to understand how it worked and realize what a technological innovation it was.

That’s the full extent of my involvement with the Citicorp Building. I didn’t tell LeMessurier there was anything wrong with his building. I knew nothing about quartering wind loads or the steel frame being bolted instead of welded. The Citicorp paper and the grade it received have receded in my memory for the following 33 years.

In summer 2011, I found out what happened to the CitiCorp building while working at a construction consulting firm in Morristown, New Jersey, where I still work, now as a Construction Risk Analyst. Our office manager offered me a book called Einstein’s Refrigerator by Steve Silverman. It’s a series of stories about strange technological facts. To my surprise, one chapter was about the CitiCorp Building.

I read about the engineering student from New Jersey and realized it was me. A chill went up my spine. After a few months, I wrote an email to LeMessurier Consultants and asked to speak to William LeMessurier, but was informed he’d died four years earlier. So that’s my strange story. I’ve told it to lots of people in the last few years and even wrote a play about it entitled The Serene Secret.

It would seem strange to come forward at this time, when new research points to the possibility that the repairs may have been in fact unnecessary, and that the student may have brought attention to a non-existing problem. Coming out now with a personal recollection is therefore not seeking the glory of having played a role in a significant engineering and ethics lesson, but simply a desire to complete a story full of surprising twists.

Lee DeCarolis is a Licensed Architect and Construction Code Official in New Jersey. He analyzes large building projects to determine construction risks prior to and during construction for banks.

References

Duthinh, D. (2018). Citicorp building repairs revisited: Answers to a fateful question asked by an undergraduate student forty years ago. Online Ethics Center. https://onlineethics.org/cases/moral-exemplars/william-lemessurier-fifty-nine-story-crisis-lesson-professional-behavior

Duthinh, D. (2020). Modern reassessment of the citicorp building design wind loads. Engineers Journal, Dublin, Ireland. https://www.engineersireland.ie/Engineers-Journal/Civil/modern-reassessment-of-the-citicorp-building-design-wind-loads

Hartley, D. L. (1978). Implications of a major urban office complex: The scientific, social, and symbolic meanings of citicorp center, New York City [senior thesis]. Princeton University.

Isyumov, N., Holmes, J. D., Surry, D., & Davenport, A.G. (1975). A study of wind effects for the first national city corporation project – New York,” USA, University of Western Ontario Research Report BLWT-SS1-75, London, Ont. Canada.

Kremer, E. (2002). (Re)examining the Citicorp Case: ethical paragon or chimera? Arq, 6(3), 269–276. https://doi.org/https://doi.org/10.1017/S1359135503001763

Park, S., Duthinh, D., Simiu, E., & Yeo, D. H. (2019). Wind effects on a tall building with square cross-section and mid-side base columns: Database-assisted design approach. Journal of Structural Engineering, 145(5), 06019001. https://doi.org/10.1061/(asce)st.1943-541x.0002328

Whitbeck, C. (n.d.). Addendum: The Diane Hartley case. Online Ethics Center. https://onlineethics.org/cases/moral-exemplars/william-lemessurier-fifty-nine-story-crisis-lesson-professional-behavior#addendum.